The Environment-Enhancing Energy (E2-E) Paradigm

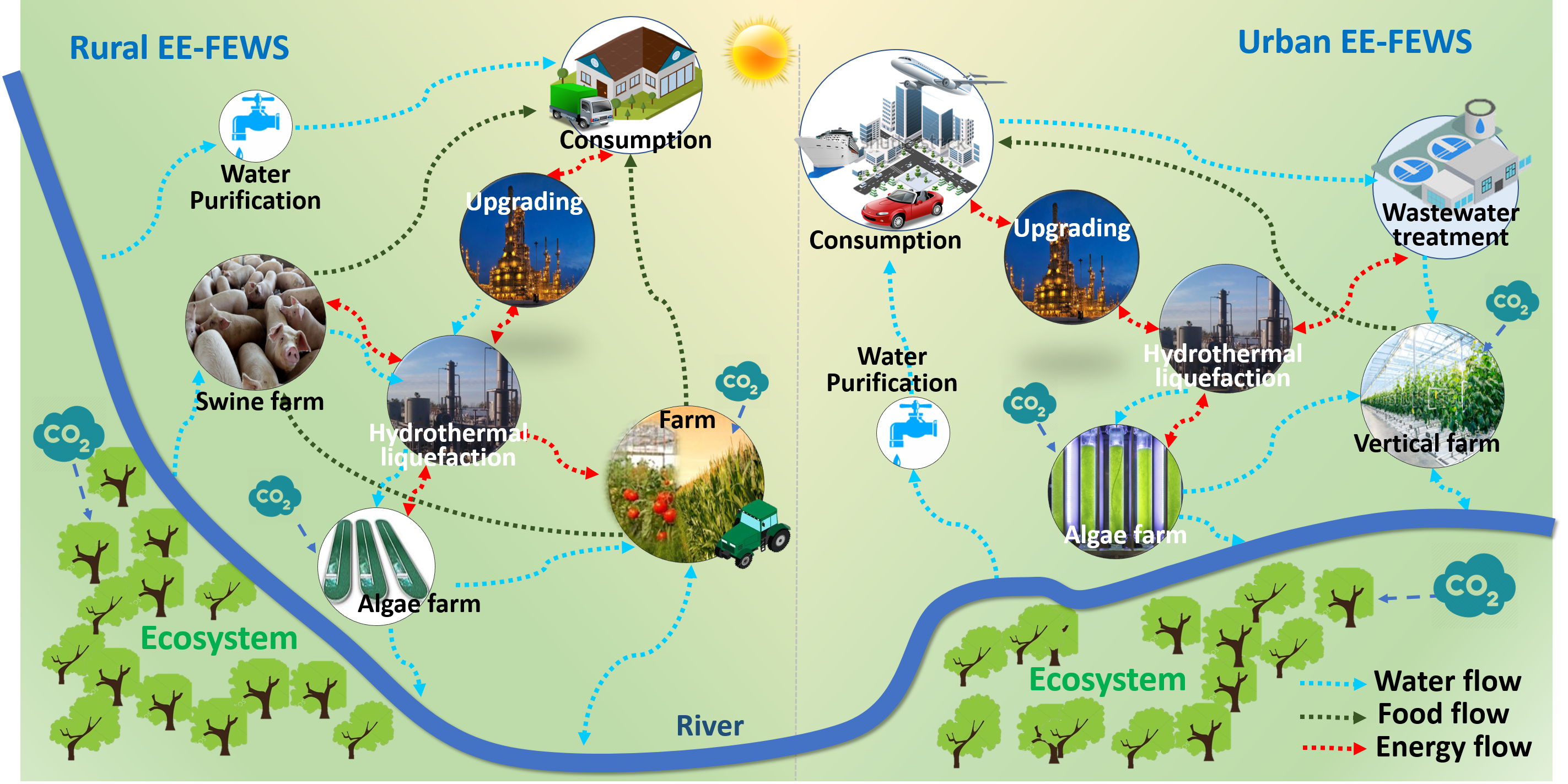

The E2-Energy paradigm draws inspiration from nature and puts energy, food, water, and environmental goals in harmony by recycling energy, nutrients, carbon, and water imbedded in biomass streams. In this approach, wet biomass (such as algae, manure, and food processing waste) is converted into biocrude oil via hydrothermal liquefaction (HTL). The biocrude oil is then upgraded into transportation fuels and chemicals such as biodiesel and biokerosene via biochemical means including distillation, catalysis, and hydrotreating. The post-HTL aqueous stream with concentrated nutrients in the original biomass can be recovered and reused for algae culturing, vegetable production, or via biochemical processes such as fermentation for the generation of more bioenergy. This synergistic approach valorizes biowaste stream and at the same time reduces carbon and nitrogen emissions.

Hydrothermal Liquefaction and Biocrude Oil Upgrading

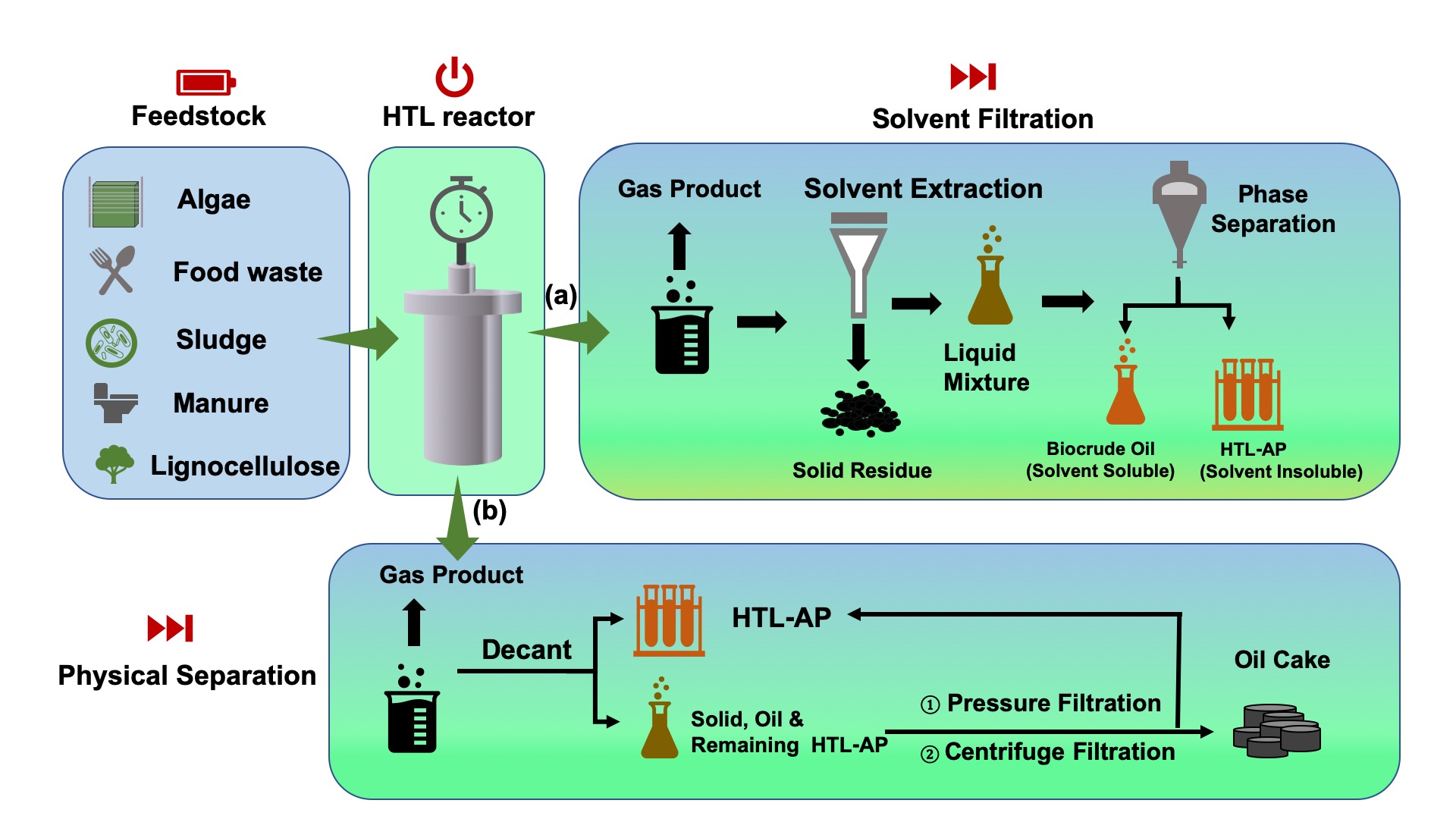

Hydrothermal liquefaction is a thermochemical conversion technology that converts wet biomass into biocrude oil at elevated temperatures (250–400°C) and pressures (4–22 MPa). Our lab focuses on the conversion of various waste substrates (crop residues, animal manure, algae, food waste, etc.) into biocrude oil and the subsequent upgrading that involves distillation, catalytic hydrotreating, and esterification to yield a high-value, high-quality oil product. In particular, we strive to produce bio-kerosene (jet fuel) that is physically and chemically similar to conventional kerosene. Our goal is to remediate waste while concomitantly producing a fuel product that can one day supplement or even supplant fossil fuel sources that lead to deleterious impacts on the environment and air.

Anaerobic Digestion

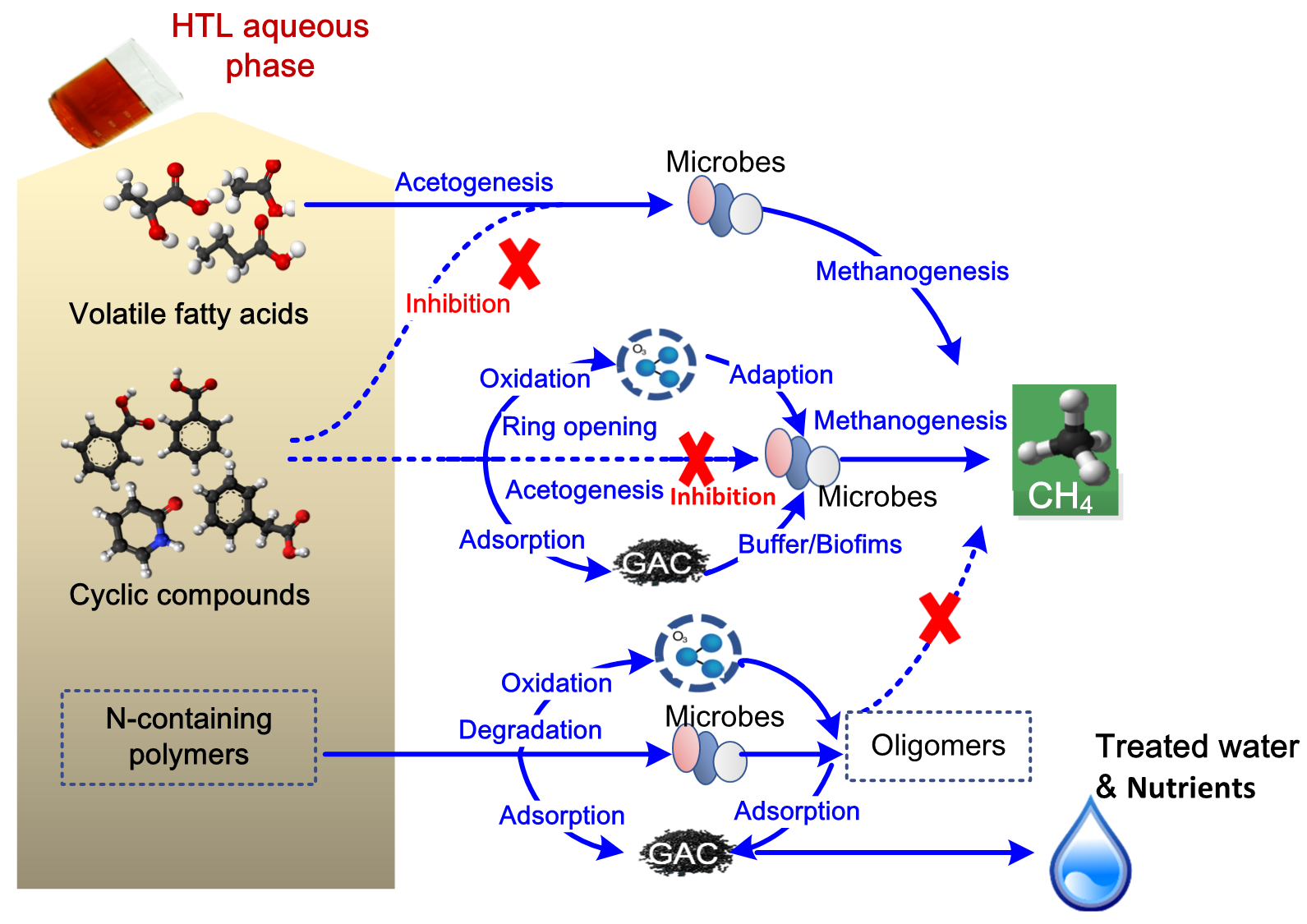

Anaerobic digestion is a widely used method for producing bioenergy from waste streams. The four major steps of anaerobic digestion include hydrolysis, acidogenesis, acetogenesis, and methanogenesis. Acetogensis and methanogenesis are the rate limiting steps and can be easily affected by environmental inhibitions. In recent years, direct interspecies electron transfer (DIET) has been proposed to improve the efficiency and stability of anaerobic digestion. DIET is a process that transfers reducing equivalents between electron donating bacteria and electron accepting archaea via biological conductive nanowires, cytochromes, or by adding conductive materials. DIET can facilitate anaerobic digestion by speeding up the start-up period, accelerating the organic conversion, and improving the methane generation. In our lab, the post hydrothermal liquefaction waste stream was collected and used for anaerobic digestion facilitated by DIET for the augmented generation of value-added biogas.

Algae Growth

Algae cultivation is an integral part of the E2-E model, as these photosynthetic microorganisms leverage nutrients, such as nitrogen, phosphorus, and metals, in the aqueous by-product derived from the hydrothermal liquefaction process (PHW). They amplify the nutrient recycling effect in the E2-E paradigm while simultaneously capturing solar energy and sequestering carbon dioxide from the atmosphere, which essentially treats wastewater and generates biomass that can be recycled back into the HTL process. Our team’s research focuses on understanding how to pre-treat PHW through dilution and how the toxicity of certain PHW refractory organic compounds confer negative effects on algae photosynthesis in order to solve key bottlenecks in value recovery.

Bioenvironmental Engineering Laboratory

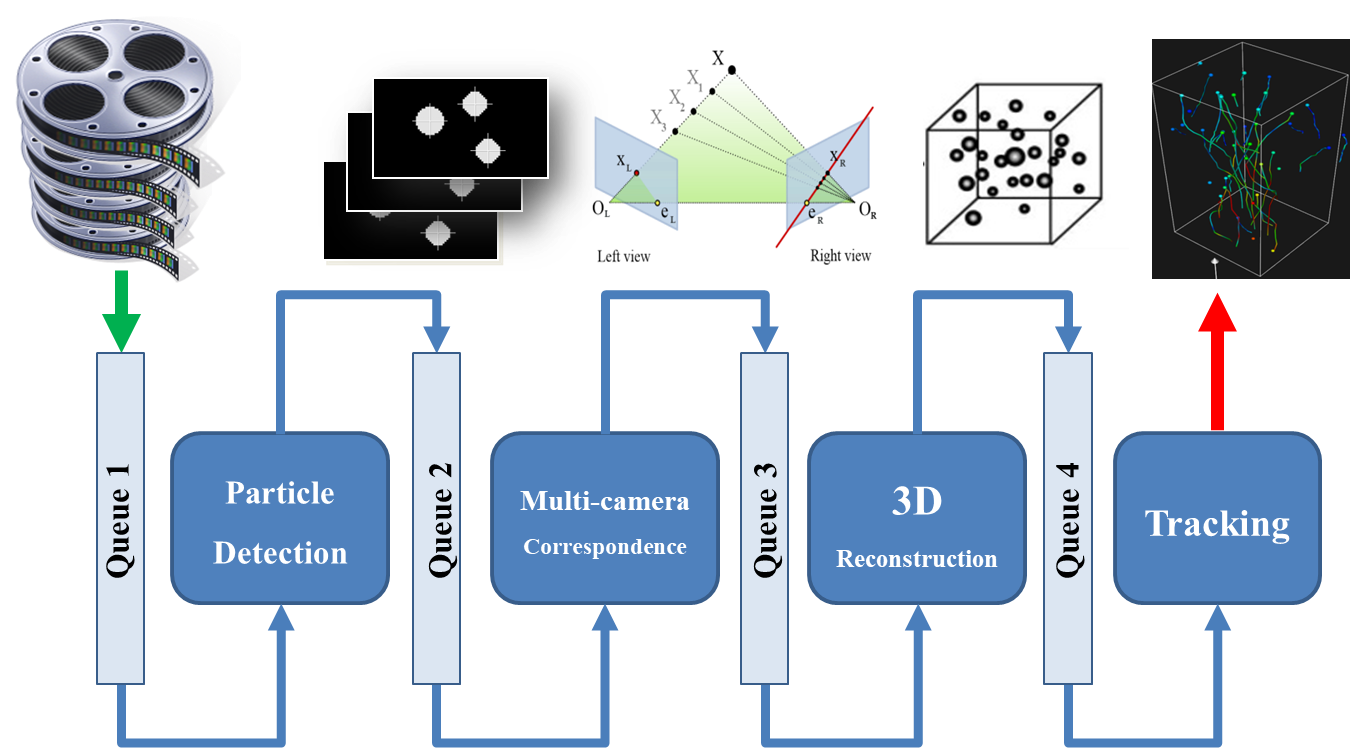

The Indoor Air Quality program encompasses three areas: 1) Volumetric Particle Tracking Velocimetry (VPTV), also referred to as Lagrangian Particle Tracking, for airflow and contaminant studies. Our team has developed a VPTV system that has the capability to measure in real-time (with less than 0.5 seconds of lag), 3-dimensional, large volume flows in terms of velocity, acceleration, pressure profiles, particle trajectories, and particle fate (such as coughing and sneezing droplets). The existing system uses eight smart cameras and can be readily scaled up to 64 cameras. 2) Aerodynamic air cleaning, also called aero-deduster, can be applied in many dusty environment air-cleaning such as for cooling system, air supply systems and animal facilities. 3) Ventilation equipment testing under the BioEnvironmental Structure and Systems (BESS) lab, serves the industry for equipment testing/development via our NIST/ASHRAE standard wind tunnel, which has a 22 m3/s of air flow capacity.

Air Particle Tracking

Volumetric Particle Tracking Velocimetry (VPTV) can be applied to an indoor and outdoor built environment to study the wind flow pattern around buildings. Measured flow patterns can be used to understand and optimize the wind environment, and pedestrian comfort and energy efficiency can be improved. As an experimental method, VPTV provides a detailed flow pattern comparable with the CFD method. However, VPTV measures real flow without setting boundary conditions and choosing a complex CFD model. For large scale VPTV measurement, illumination is complex and the patterns of particle image are too complex to be represented by a simple model. To address this problem, our research incorporates a machine learning technique to learn the pattern of particle images. A support Vector Machine (SVM) model is also chosen to learn the particle image pattern using training images generated by Ray Tracing. With the SVM model, a particle image is identified and the centroid of the particle image is calculated more accurately.

Air Cleaning

As air is utmost important yet basic need to us and other creatures, its quality crucially impacts our physical and mental health. It is also a primary medium for equipment use such as heat exchanger and HVAC system. The quality of the air directly will directly affect the wellbeing and performance of our biological beings as well as machines. Our lab aims to characterize and ultimately separate the aerosols that are present in the air which can be dangerous to us and equipment, common ones including solid particles like dusts, liquid such as droplets and even toxic gases. We use cutting-edge instruments to understand the properties of aerosols in concerns, and then use computer simulations and CAD to formulate a suitable design of aerodynamic air cleaning devices which we call them Dedusters. Finally, we evaluate the performance of prototypes built from rapid prototyping techniques.